Views: 0 Author: Site Editor Publish Time: 2025-05-12 Origin: Site

When embarking on a landscaping, construction, or infrastructure project, one of the most overlooked yet critical components is geotextile. You might be wondering, "Do I really need geotextile under gravel?" The short answer is a resounding yes—especially if your goal is to enhance durability, improve drainage, and reduce long-term maintenance.

Whether you're constructing a driveway, building a garden path, or undertaking a major transport construction project, incorporating geotextile fabric can save you time, effort, and money. This article delves into everything you need to know about geotextile, how it functions under gravel, its applications in various sectors like highways, port facilities, and coast reclamation works, and what options are best suited for your needs, especially from reputable suppliers like Yingfan.

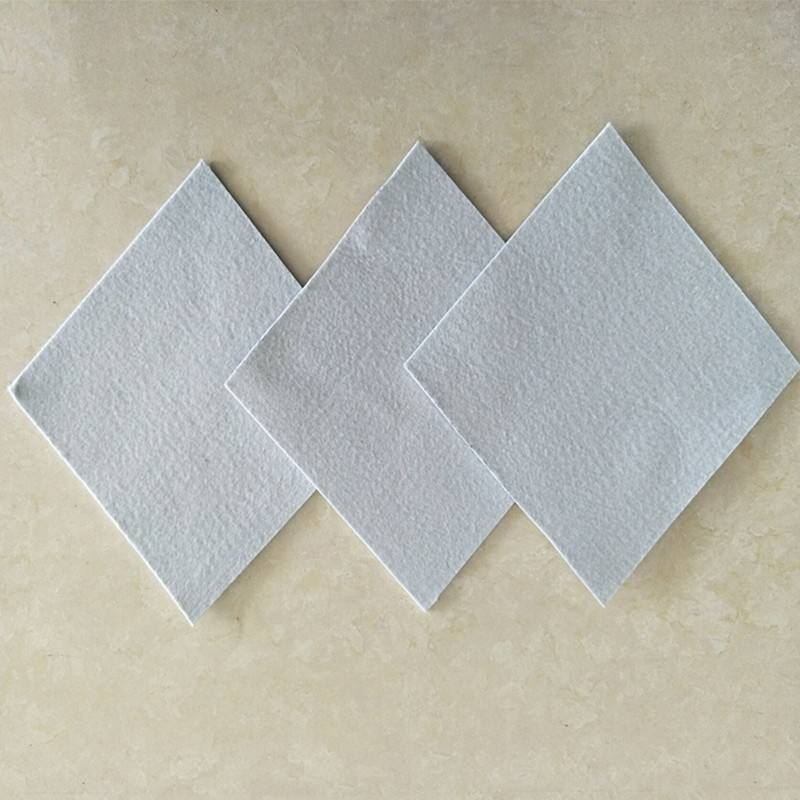

Geotextile is a permeable fabric made from synthetic fibers such as polypropylene or polyester. Its primary function is to improve soil stability, provide separation, and enhance drainage. It comes in several forms, including woven geotextile, non-woven geotextile, and composite versions, with specific designs for diverse applications.

| Type | Material | Properties | Applications |

|---|---|---|---|

| Non-woven Geotextile | Polypropylene or PET | High permeability | Drainage, filtration |

| Woven Geotextile | Polypropylene or PET woven geotextile | High tensile strength | Road stabilization, erosion control |

| Geotextile Grid | Integrated geogrid | Combines reinforcement & separation | High-load areas, retaining walls |

The geotextile membrane acts as a barrier between different soil layers, preventing the intermixing of gravel and soil, which otherwise could lead to sinking or rutting over time.

Installing geotextile fabric under gravel creates a foundation that is more stable, better draining, and longer lasting. Here’s why:

Separation: Prevents gravel from sinking into the soil.

Reinforcement: Enhances load distribution.

Drainage: Allows water to pass while retaining soil particles.

Weed Prevention: Acts as a barrier to unwanted growth.

Longevity: Reduces maintenance and replacement costs.

This is especially crucial for surfaces with regular traffic like driveways, paths, or parking lots, as well as for structural projects in highways and port facilities. Durable geotextile fabric for gravel driveways and PET woven geotextile for erosion control are increasingly used for home and commercial applications.

While both geogrid and geotextile serve structural purposes, they are distinct in their composition and function.

| Feature | Geotextile | Geogrid |

| Material | Polypropylene or polyester fabric | Polymer grid structure |

| Function | Separation, filtration, drainage | Reinforcement |

| Flexibility | High | Low |

| Use Case | Drainage geotextile, soil filtration | Load-bearing areas |

In some projects, particularly in coast reclamation works or waste and chemical management, combining geogrid vs geotextile delivers superior performance.

Using woven geotextile in road beds prevents aggregate contamination and improves the load-bearing capacity of roads. PET woven geotextile for road base is widely adopted due to its strength and durability.

Geotextile containers are used for shoreline protection and sediment containment. These containers are filled with sand or soil and act as both barriers and foundational supports in coast reclamation works. Marine geotextile for shoreline stabilization is a preferred material in these applications.

Railway beds, airport runways, and transit lines benefit from geotextile membrane for subgrade stabilization, preventing soil migration and enhancing durability. Geotextile for railway track bed is now standard in many large-scale projects.

Landfills and hazardous waste sites often use drainage geotextile for leachate control and liners to prevent seepage. Geotextile for chemical waste barrier systems is essential for environmental protection.

Shanghai Yingfan Engineering Material Co., Ltd. is a reliable supplier with a full range of geotextile options. Their offerings include:

Short Fiber Needle Punched Nonwoven Geotextile: Best for general drainage and separation.

PET Woven Geotextile: Ideal for load-bearing applications like roads and embankments.

Geotextile Containers: Useful in shoreline and sediment control.

Their products comply with ASTM and Chinese national standards, and are certified under ISO 9001, 14001, and 45001.

| Product | Best Use | Strength | Permeability | Availability |

| PET Woven Geotextile | Roads, highways | High | Medium | ✔️ |

| Nonwoven Geotextile | Gardens, light traffic areas | Medium | High | ✔️ |

| Geotextile Membrane | Drainage, landscaping | Variable | High | ✔️ |

Site Preparation: Clear vegetation and debris.

Base Leveling: Smooth the area and remove large stones.

Lay the Geotextile: Roll out the fabric ensuring overlaps of at least 30 cm.

Anchor Edges: Secure with pins or staples.

Add Gravel Layer: Spread uniformly and compact.

This simple installation improves gravel stability and minimizes long-term repair needs. Installing pet woven geotextile under gravel ensures better load distribution and longevity, particularly for driveways and walkways.

A1: Geotextile is a permeable fabric used to improve soil stability, provide separation, and enhance drainage in construction projects. It prevents intermixing of soil and gravel, which increases durability and reduces maintenance.

A2: PET woven geotextile has higher tensile strength, making it ideal for load-bearing applications like roads. Nonwoven versions are better for drainage and landscaping.

A3: Absolutely. It prevents gravel from sinking and mixes with the soil underneath, keeping your driveway stable and low-maintenance.

A4: Geotextile containers are used in marine and reclamation works to contain sediment or serve as protective barriers in shoreline environments.

A5: Drainage geotextile is superior for filtering and allowing water flow while blocking sediment. Geogrid is mainly used for reinforcement, not filtration.

A6: When properly installed, geotextile fabric can last several decades, particularly products from certified manufacturers like Yingfan.

A7: Yes, the gravel acts as the structural layer, and the geotextile provides the foundational support beneath it.

A8: Yes, Yingfan's products are free of harmful additives and are made with environmentally friendly materials that comply with international environmental standards.

So, do you need geotextile under gravel? If you care about project longevity, maintenance costs, and structural integrity, the answer is clearly yes. Especially for heavy-use or environmentally sensitive areas like highways, coast reclamation works, and waste and chemical management zones, geotextile plays a pivotal role.

For the best in class solutions, consider PET woven geotextile and drainage geotextile products from Yingfan. With years of industry expertise and internationally recognized quality certifications, Yingfan provides versatile, high-performance products that meet modern engineering demands.

Integrating geotextile fabric into your project isn’t just a smart choice; it’s a future-proof one. DIY users, engineers, and contractors alike benefit from high-quality options such as gravel driveway geotextile fabric and heavy-duty woven geotextile for load support, all available from a trusted supplier like Yingfan.