| Tensile: | |

|---|---|

| Size: | |

| Availability: | |

35-200kn/m

Yingfan

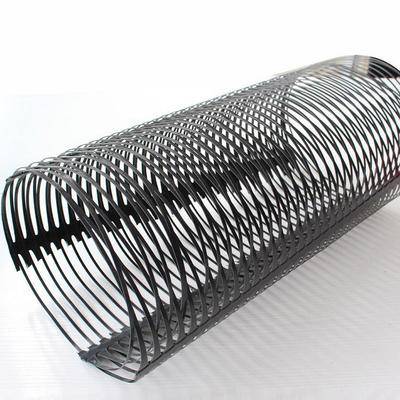

Yingfan’s High Strength PP/HDPE Uniaxial Plastic Geogrid is a top-tier geosynthetic reinforcement material designed for civil engineering projects requiring robust soil stabilization. Crafted from high-molecular PP (Polypropylene) or HDPE (High-Density Polyethylene), it is manufactured through extrusion, punching into regular mesh patterns, and longitudinal stretching—creating a structure with exceptional tensile strength (35-200kn/m) and modulus. This Uniaxial Geogrid excels in reinforcing soft ground, retaining walls, slopes, and dams, forming a strong interlock with soil and gravel to distribute loads, prevent deformation, and enhance structural stability. Trusted by engineers worldwide, it is the ideal choice for road, railway, and infrastructure projects demanding long-term reliability.

Item | Details |

Product Name | High Strength PP/HDPE Uniaxial Plastic Geogrid |

Material | Premium PP (Polypropylene) / HDPE (High-Density Polyethylene) |

Tensile Strength Range | 35-200kn/m (warp/weft direction) |

Width | 2m - 4m (customizable) |

Mesh Size | 225mm×18mm (or per customer’s customization) |

Core Feature | Primary strength in machine direction, stable aperture structure |

Application Standard | Compliant with global geogrid construction norms |

Technical data sheet for PP uniaxial geogrid

Product Spec. | Ultimate Tensile Strength MD kN/m ≥ | Tensile strength @ 2% MD kN/m ≥ | Tensile strength @ 5% MD kN/m ≥ | Elongation at ultimate tensile strength MD % ≤ |

TGDG35 | 35.0 | 10.0 | 22.0 | 10.0 |

TGDG50 | 50.0 | 12.0 | 28.0 | |

TGDG80 | 80.0 | 26.0 | 48.0 | |

TGDG120 | 120.0 | 36.0 | 72.0 | |

TGDG160 | 160.0 | 45.0 | 90.0 | |

TGDG200 | 200.0 | 68.0 | 145.0 |

Technical data sheet for HDPE uniaxial geogrid

Product Spec. | Ultimate Tensile Strength MD kN/m ≥ | Tensile strength @ 2% MD kN/m ≥ | Tensile strength @ 5% MD kN/m ≥ | Elongation at ultimate tensile strength MD % ≤ |

TGDG35 | 35.0 | 7.5 | 21.5 | 12.0 |

TGDG50 | 50.0 | 12.0 | 23.0 | |

TGDG80 | 80.0 | 21.0 | 40.0 | |

TGDG120 | 120.0 | 33.0 | 65.0 | |

TGDG160 | 160.0 | 47.0 | 93.0 |

The choice of PP/HDPE ensures superior durability: PP offers excellent creep resistance and chemical stability, while HDPE provides enhanced impact resistance and low-temperature flexibility. The manufacturing process—extrusion → punching → longitudinal stretching—aligns polymer molecules in the load-bearing direction, maximizing tensile strength. The regular mesh design enables tight interlocking with soil particles and gravel, transferring forces effectively and preventing lateral displacement. Unlike traditional reinforcement materials, this plastic geogrid is lightweight, corrosion-resistant, and easy to install, reducing construction time and labor costs.

Exceptional Tensile Strength & Modulus: With a tensile range of 35-200kn/m, it withstands high loads and prevents soil deformation in soft ground projects.

Strong Soil-Gravel Interlock: The open mesh structure interlocks tightly with aggregates, enhancing friction and improving load distribution.

Durable & Weather Resistant: Resists UV radiation, chemical erosion, and biological degradation, ensuring long service life in outdoor environments.

Stable Aperture Structure: Maintains mesh integrity under pressure, avoiding collapse and ensuring consistent reinforcement performance.

Cost-Effective & Efficient: Lightweight design reduces transportation and installation costs; compatible with various construction methods.

Customizable Specifications: Tensile strength, width, and mesh size can be tailored to meet project-specific requirements.

Ideal for reinforcing soft subgrades of highways, railways, and airports. Reduces settlement, distributes traffic loads evenly, and improves roadbed bearing capacity.

Critical for retaining wall geogrid applications—strengthens backfill soil, resists lateral pressure, and prevents wall deformation or collapse. Suitable for gravity walls, modular block walls, and reinforced soil walls.

Used in highway, railway, and mining slopes to prevent soil erosion and landslides. The geogrid anchors surface soil, enhances stability, and supports vegetation growth for ecological restoration.

Reinforces dams, dikes, and embankments to resist water pressure and soil liquefaction, ensuring structural safety in hydraulic engineering projects.

Strengthens foundations of ports, docks, and freight yards—handling heavy loads from containers and machinery while minimizing ground settlement.

Yingfan adheres to strict quality control protocols during production, from raw material inspection to final product testing. Each roll of Uniaxial Plastic Geogrid undergoes tensile strength, aperture stability, and aging resistance tests to ensure compliance with industry standards. The product is non-toxic, environmentally friendly, and does not contaminate soil or groundwater. Its stable performance under extreme conditions (temperature range: -40℃ to 80℃) makes it suitable for global construction projects.

Prepare the base: Level and compact the soil/gravel base, removing sharp objects that may puncture the geogrid.

Unroll and lay: Lay the geogrid longitudinally along the load direction (e.g., road length), overlapping edges by 15-20cm; secure with anchor stakes (spacing: 1-2m).

Backfill: Fill with soil or gravel in layers (each layer ≤30cm), compacting thoroughly to ensure interlock with the geogrid. Avoid heavy machinery directly rolling on the geogrid.

Inspect the geogrid during and after construction for damage; repair tears with geogrid patches and adhesive.

Monitor retaining walls or slopes for displacement; reinforce with additional geogrid layers if needed.

Avoid exposing the geogrid to direct sunlight for more than 48 hours before backfilling to prevent UV degradation.

Uniaxial geogrids provide primary strength in the machine direction (longitudinal) with minimal cross-directional strength (to maintain apertures). Biaxial geogrids offer equal strength in both machine and cross-machine directions, suitable for multi-directional load-bearing.

Three main types: Uniaxial, Biaxial, and Triaxial—each designed for specific applications based on tensile strength and load direction requirements.

2-5 days for in-stock products; 10-15 days for customized orders, depending on quantity.

Yes, we offer free geogrid samples to help you test quality before placing bulk orders.

Elevate your project’s stability with Yingfan’s High Strength PP/HDPE Uniaxial Geogrid! Whether for retaining walls, soft ground stabilization, or slope protection, our product delivers unmatched performance and durability. Contact our engineering team today to request a free sample, get technical support, or obtain a competitive quote. Click “Add to Basket” or email [xieruiqing@shyfem.com]—partner with Yingfan for reliable geosynthetic solutions that stand the test of time!

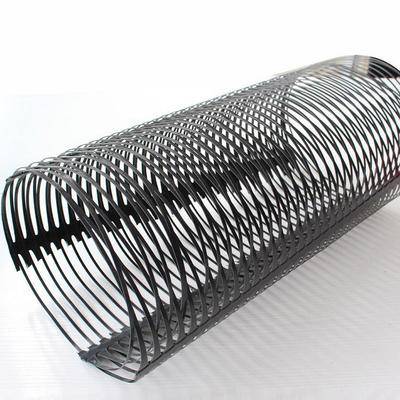

Yingfan’s High Strength PP/HDPE Uniaxial Plastic Geogrid is a top-tier geosynthetic reinforcement material designed for civil engineering projects requiring robust soil stabilization. Crafted from high-molecular PP (Polypropylene) or HDPE (High-Density Polyethylene), it is manufactured through extrusion, punching into regular mesh patterns, and longitudinal stretching—creating a structure with exceptional tensile strength (35-200kn/m) and modulus. This Uniaxial Geogrid excels in reinforcing soft ground, retaining walls, slopes, and dams, forming a strong interlock with soil and gravel to distribute loads, prevent deformation, and enhance structural stability. Trusted by engineers worldwide, it is the ideal choice for road, railway, and infrastructure projects demanding long-term reliability.

Item | Details |

Product Name | High Strength PP/HDPE Uniaxial Plastic Geogrid |

Material | Premium PP (Polypropylene) / HDPE (High-Density Polyethylene) |

Tensile Strength Range | 35-200kn/m (warp/weft direction) |

Width | 2m - 4m (customizable) |

Mesh Size | 225mm×18mm (or per customer’s customization) |

Core Feature | Primary strength in machine direction, stable aperture structure |

Application Standard | Compliant with global geogrid construction norms |

Technical data sheet for PP uniaxial geogrid

Product Spec. | Ultimate Tensile Strength MD kN/m ≥ | Tensile strength @ 2% MD kN/m ≥ | Tensile strength @ 5% MD kN/m ≥ | Elongation at ultimate tensile strength MD % ≤ |

TGDG35 | 35.0 | 10.0 | 22.0 | 10.0 |

TGDG50 | 50.0 | 12.0 | 28.0 | |

TGDG80 | 80.0 | 26.0 | 48.0 | |

TGDG120 | 120.0 | 36.0 | 72.0 | |

TGDG160 | 160.0 | 45.0 | 90.0 | |

TGDG200 | 200.0 | 68.0 | 145.0 |

Technical data sheet for HDPE uniaxial geogrid

Product Spec. | Ultimate Tensile Strength MD kN/m ≥ | Tensile strength @ 2% MD kN/m ≥ | Tensile strength @ 5% MD kN/m ≥ | Elongation at ultimate tensile strength MD % ≤ |

TGDG35 | 35.0 | 7.5 | 21.5 | 12.0 |

TGDG50 | 50.0 | 12.0 | 23.0 | |

TGDG80 | 80.0 | 21.0 | 40.0 | |

TGDG120 | 120.0 | 33.0 | 65.0 | |

TGDG160 | 160.0 | 47.0 | 93.0 |

The choice of PP/HDPE ensures superior durability: PP offers excellent creep resistance and chemical stability, while HDPE provides enhanced impact resistance and low-temperature flexibility. The manufacturing process—extrusion → punching → longitudinal stretching—aligns polymer molecules in the load-bearing direction, maximizing tensile strength. The regular mesh design enables tight interlocking with soil particles and gravel, transferring forces effectively and preventing lateral displacement. Unlike traditional reinforcement materials, this plastic geogrid is lightweight, corrosion-resistant, and easy to install, reducing construction time and labor costs.

Exceptional Tensile Strength & Modulus: With a tensile range of 35-200kn/m, it withstands high loads and prevents soil deformation in soft ground projects.

Strong Soil-Gravel Interlock: The open mesh structure interlocks tightly with aggregates, enhancing friction and improving load distribution.

Durable & Weather Resistant: Resists UV radiation, chemical erosion, and biological degradation, ensuring long service life in outdoor environments.

Stable Aperture Structure: Maintains mesh integrity under pressure, avoiding collapse and ensuring consistent reinforcement performance.

Cost-Effective & Efficient: Lightweight design reduces transportation and installation costs; compatible with various construction methods.

Customizable Specifications: Tensile strength, width, and mesh size can be tailored to meet project-specific requirements.

Ideal for reinforcing soft subgrades of highways, railways, and airports. Reduces settlement, distributes traffic loads evenly, and improves roadbed bearing capacity.

Critical for retaining wall geogrid applications—strengthens backfill soil, resists lateral pressure, and prevents wall deformation or collapse. Suitable for gravity walls, modular block walls, and reinforced soil walls.

Used in highway, railway, and mining slopes to prevent soil erosion and landslides. The geogrid anchors surface soil, enhances stability, and supports vegetation growth for ecological restoration.

Reinforces dams, dikes, and embankments to resist water pressure and soil liquefaction, ensuring structural safety in hydraulic engineering projects.

Strengthens foundations of ports, docks, and freight yards—handling heavy loads from containers and machinery while minimizing ground settlement.

Yingfan adheres to strict quality control protocols during production, from raw material inspection to final product testing. Each roll of Uniaxial Plastic Geogrid undergoes tensile strength, aperture stability, and aging resistance tests to ensure compliance with industry standards. The product is non-toxic, environmentally friendly, and does not contaminate soil or groundwater. Its stable performance under extreme conditions (temperature range: -40℃ to 80℃) makes it suitable for global construction projects.

Prepare the base: Level and compact the soil/gravel base, removing sharp objects that may puncture the geogrid.

Unroll and lay: Lay the geogrid longitudinally along the load direction (e.g., road length), overlapping edges by 15-20cm; secure with anchor stakes (spacing: 1-2m).

Backfill: Fill with soil or gravel in layers (each layer ≤30cm), compacting thoroughly to ensure interlock with the geogrid. Avoid heavy machinery directly rolling on the geogrid.

Inspect the geogrid during and after construction for damage; repair tears with geogrid patches and adhesive.

Monitor retaining walls or slopes for displacement; reinforce with additional geogrid layers if needed.

Avoid exposing the geogrid to direct sunlight for more than 48 hours before backfilling to prevent UV degradation.

Uniaxial geogrids provide primary strength in the machine direction (longitudinal) with minimal cross-directional strength (to maintain apertures). Biaxial geogrids offer equal strength in both machine and cross-machine directions, suitable for multi-directional load-bearing.

Three main types: Uniaxial, Biaxial, and Triaxial—each designed for specific applications based on tensile strength and load direction requirements.

2-5 days for in-stock products; 10-15 days for customized orders, depending on quantity.

Yes, we offer free geogrid samples to help you test quality before placing bulk orders.

Elevate your project’s stability with Yingfan’s High Strength PP/HDPE Uniaxial Geogrid! Whether for retaining walls, soft ground stabilization, or slope protection, our product delivers unmatched performance and durability. Contact our engineering team today to request a free sample, get technical support, or obtain a competitive quote. Click “Add to Basket” or email [xieruiqing@shyfem.com]—partner with Yingfan for reliable geosynthetic solutions that stand the test of time!