Views: 0 Author: Site Editor Publish Time: 2026-02-02 Origin: Site

Seepage control is a serious engineering challenge.So, what is geosynthetic clay liner in modern projects?This article explains the geosynthetic clay liner definition and how a GCL liner works.You will learn key uses, benefits, and comparisons, including trusted solutions from Yingfan.

The geosynthetic clay liner definition is simple but powerful. It is a factory-manufactured hydraulic barrier designed to prevent seepage of liquids or gases. Instead of using hundreds of millimeters of compacted soil, engineers can use a thin GCL liner that performs the same containment role. A geosynthetic clay liner usually contains sodium bentonite clay, which forms a dense impermeable layer once hydrated. This makes it a key solution for landfill liner systems and environmental protection. The main purpose is to protect groundwater and prevent contamination. It is widely applied in waste management, mining containment, and water storage projects because it delivers consistent sealing performance in a compact form.

Many engineers ask, how does a geosynthetic clay liner work in real conditions. The answer lies in bentonite swelling. When water enters the liner, the bentonite absorbs moisture and expands, sometimes many times its original volume. This swelling creates a gel-like seal that blocks fluid migration. Because of this, geosynthetic clay liner waterproofing applications are very effective even under high hydraulic pressure. Another key feature is self-healing. If a small puncture occurs, bentonite can expand into the void and reseal it. This combination of swelling, low permeability, and self-repair makes a GCL liner a trusted containment system, and it is a core feature highlighted in advanced GCL solutions offered by brands like Yingfan.

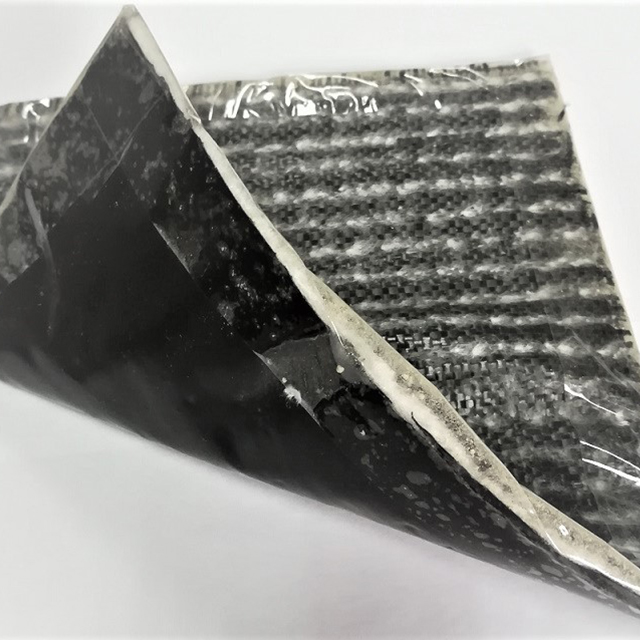

A typical GCL liner is made from three main components. The core is a bentonite clay liner layer, usually sodium bentonite, which provides the hydraulic barrier. Around this clay core are two geotextile layers, woven or non-woven, that give strength and protection. These layers are bonded using needle punching, stitching, or adhesives. Bonding improves shear resistance and keeps the liner stable during installation. Together, these components create an engineered geosynthetic barrier that is thin, durable, and easy to deploy across large containment sites.

The bentonite liner is the heart of every geosynthetic clay liner. Sodium bentonite has a unique ability to swell when hydrated. This swelling forms a dense, low-permeability barrier that can stop leachate and contaminated liquids. Bentonite is rich in expansive clay minerals, often dominated by montmorillonite, which gives it strong sealing capacity. Because of its hydraulic conductivity, a bentonite geosynthetic clay liner can outperform many natural soil liners. Engineers choose this material because it offers consistent containment, even in projects where groundwater protection is critical. The clay core is also what allows self-sealing performance, which reduces leakage risks over decades.

Geotextile layers play an important role in a geosynthetic clay liner system. They protect the bentonite core from erosion and help maintain structural integrity during handling. They also provide tensile strength, which supports installation on slopes or uneven ground. Without geotextiles, the clay could shift or mix with surrounding soils. The geotextile layers also assist filtration and separation functions in containment systems. This reinforcement is why a GCL liner can be installed quickly while still delivering reliable performance. It is one reason why geosynthetic barriers are preferred in large infrastructure and landfill projects.

Bonding methods affect the durability and performance of geosynthetic clay liners. Needle punching mechanically locks fibers through the bentonite core, creating strong internal shear resistance. This is especially important for slope stability in landfill caps. Adhesive bonding uses chemical agents to hold layers together, which may suit certain flat applications. Stitching can also provide reinforcement in some designs. Each method impacts strength, flexibility, and installation behavior. Selecting the right bonding approach depends on site geometry, hydraulic gradients, and stress conditions. Understanding these construction differences helps engineers match the correct GCL liner type to project requirements.

The primary feature of a geosynthetic clay liner is its hydraulic barrier capability. When bentonite hydrates, it forms a seal with extremely low permeability. This allows GCL liners to prevent seepage of water, leachate, or hazardous fluids. Compared with compacted clay liners, GCLs often achieve lower hydraulic conductivity while using far less thickness. This makes them attractive for projects with limited space. Their engineered consistency also improves reliability across large sites. Because seepage control is a major environmental requirement, geosynthetic clay liner for landfill containment remains one of the most important applications worldwide.

Self-healing is a major advantage of bentonite geosynthetic clay liner products. If small punctures or cracks occur during installation, bentonite swelling can fill the void and restore sealing performance. This property provides extra security compared with some traditional liners that may require immediate repair. Self-healing also reduces long-term leakage risks, especially in landfill and mining environments. It does not eliminate the need for careful installation, but it improves resilience. Engineers often see this feature as an insurance layer in containment design, supporting long-term environmental protection.

Geosynthetic clay liners are designed for long-term durability. They resist chemical degradation and maintain sealing integrity under stress. In mining projects, liners may face aggressive chemicals, high loads, and harsh climates. In landfill caps, they must endure settlement and moisture changes. A well-designed GCL liner can perform for decades when protected by proper cover soils. Durability also reduces maintenance costs and improves lifecycle value. This is why geosynthetic barriers are widely adopted in demanding civil engineering projects that require reliable containment.

Tip: Always evaluate site chemistry and hydraulic gradients before selecting a GCL liner type.

The most common use of geosynthetic clay liner systems is landfill containment. Landfills produce leachate, which can contaminate groundwater if not properly controlled. A GCL liner acts as a strong hydraulic barrier beneath waste cells or as part of a landfill cap. Because it is factory manufactured, it provides consistent performance compared with field-compacted clay. Many regulations require strict seepage prevention, making landfill liner systems one of the largest markets for GCL liners. Their self-sealing and low permeability make them reliable solutions for long-term waste containment.

Geosynthetic clay liner for mining projects is critical in tailings dams and heap leach pads. Mining operations often involve toxic chemicals that must not escape into soil or water systems. A bentonite liner provides strong containment, reducing environmental risk. The geotextile reinforcement supports stability under heavy loads. In tailings facilities, seepage control is essential for both safety and compliance. GCL liners offer a practical solution because they are easier to install than thick clay layers. Their durability under harsh conditions makes them valuable in mining containment engineering.

Water containment is another major application. Reservoirs, canals, ponds, and wastewater treatment lagoons all require seepage control. Geosynthetic clay liner waterproofing applications help prevent water loss and protect surrounding soils. GCL liners are especially useful where space is limited or where importing clay is expensive. Their thin design allows efficient construction while still achieving strong barrier performance. Many municipal and industrial water projects now use GCL liners as part of composite lining systems to ensure long-term containment.

Beyond waste and water containment, geosynthetic clay liners are used in infrastructure projects. Underground parking garages, tunnels, and basements often need waterproof liner systems. A GCL liner placed beneath structures can reduce groundwater infiltration. They are also used in road and railway construction for subgrade stabilization. These applications highlight the versatility of geosynthetic barriers. They support both environmental protection and infrastructure resilience, making them valuable across many engineering sectors.

One key difference between a geosynthetic clay liner and a compacted clay liner is thickness. Compacted clay liners may require 300 to 900 millimeters of soil, while a GCL liner is only a few millimeters thick. This saves excavation effort and increases usable containment volume. Factory manufacturing ensures quality control, while compacted clay depends heavily on field labor and moisture conditions. Engineers often prefer GCL liners because they provide predictable hydraulic performance in a much thinner profile.

Feature | Geosynthetic Clay Liner (GCL) | Compacted Clay Liner (CCL) |

Thickness | ~6 mm | 300–900 mm |

Manufacturing | Factory-made | Field-built |

Installation speed | Rapid | Slow |

Quality consistency | High | Workforce dependent |

Geosynthetic clay liner installation guide practices emphasize speed and simplicity. GCL liners come in wide rolls, allowing rapid deployment. Compacted clay requires careful placement, moisture conditioning, and repeated compaction. This makes construction slower and more complex. Quality control is critical for both systems, but GCL liners reduce variability because they are manufactured under controlled conditions. Faster installation also lowers labor costs and reduces project delays, which is important for large landfill or mining developments.

Cost is not only about initial price. A GCL liner may have a competitive installed cost because it reduces labor and construction time. Lifecycle benefits include durability, self-healing, and lower maintenance needs. Compacted clay liners may require more space and more intensive quality control. Over decades, GCL liners often deliver better cost efficiency. Engineers evaluate total cost of ownership, including risk reduction and environmental compliance, when selecting containment systems.

Proper installation begins with site preparation. The subgrade must be smooth, clean, and free of sharp objects. Debris can puncture the liner and reduce performance. The surface should be level to ensure uniform contact. Inspecting rolls before placement ensures material quality. These preparation steps reduce risk and improve long-term sealing. Good practice follows established geosynthetic clay liner installation guide standards, which stress disciplined field procedures.

Seams and overlaps are critical for containment integrity. Panels must overlap correctly to prevent leakage paths. Depending on design, overlaps may require bentonite paste or other treatments. After placement, cover soil is applied to protect the liner from damage and premature hydration. Compaction ensures intimate contact between liner and subgrade. These steps are essential for achieving continuous barrier performance in landfill containment or water storage projects.

Installation Step | Key Goal | Common Risk if Ignored |

Subgrade cleaning | Prevent punctures | Damage and leakage |

Correct overlaps | Seal panel joints | Seepage pathways |

Protective cover soil | Avoid exposure | Bentonite erosion |

Quality inspection | Ensure compliance | Hidden defects |

Quality assurance ensures that installation meets design requirements. Crews must check overlap widths, cover thickness, and damage repairs. Hydration conditions should be controlled to prevent premature swelling before confinement. Regular inspections reduce failure risk and support long-term durability. In large projects, QA procedures are often as important as the liner material itself. A well-installed geosynthetic clay liner can provide decades of containment performance.

Tip: Document seam inspections and repairs carefully for regulatory compliance.

Selecting the right geosynthetic clay liner depends on project conditions. Landfills need strong leachate containment, while mining sites may require chemical resistance. Water reservoirs focus on seepage prevention and durability. Engineers must consider soil conditions, hydraulic gradients, and contaminant types. Matching liner specifications to site demands ensures effective containment. Poor selection can lead to costly remediation later, so design alignment is critical.

Some projects require coated GCL liners for added gas or chemical protection. Reinforced liners provide higher shear strength on slopes. These options expand the range of geosynthetic barriers available. Coatings can reduce desiccation risk and improve long-term stability. Reinforced products are valuable in landfill caps or steep embankments. Choosing the right variant depends on risk factors and performance goals, and Yingfan offers needle-punched GCL solutions that emphasize strong self-healing and low permeability performance for these demanding scenarios.

GCL Type | Best Use Case | Added Benefit |

Standard GCL liner | Flat containment areas | Cost efficiency |

Reinforced needle-punched GCL | Slopes and embankments | Higher shear strength |

Coated GCL liner | Gas or chemical control sites | Extra protection layer |

Reliable bentonite geosynthetic clay liner manufacturers provide tested and consistent products. Key specifications include bentonite mass, tensile strength, peel strength, and hydraulic conductivity. Standards such as ASTM guide performance evaluation. Supplier expertise supports correct selection, delivery, and technical guidance. Material consistency is essential for long-term containment reliability, especially in regulated landfill or mining projects.

Note: Always verify liner specifications against project design needs and local regulations.

A geosynthetic clay liner is a factory-made hydraulic barrier using bentonite and geotextiles.Its swelling and self-healing create low-permeability protection for critical containment.GCL liners support landfills, mining sites, reservoirs, and waterproof infrastructure projects.With trusted GCL solutions, Yingfan helps engineers reduce seepage risk and protect groundwater long term.

A: A geosynthetic clay liner is a factory-made hydraulic barrier using bentonite and geotextiles for seepage control.

A: Geosynthetic clay liner for landfill containment helps stop leachate and protects groundwater in waste projects.

A: It swells when hydrated, forming a dense seal. This makes geosynthetic clay liner waterproofing applications very effective.

A: Geosynthetic clay liner vs geomembrane depends on site needs. GCL offers self-healing, while geomembranes provide strong synthetic barriers.