| Availability: | |

|---|---|

3000-6500g/m2

Yingfan

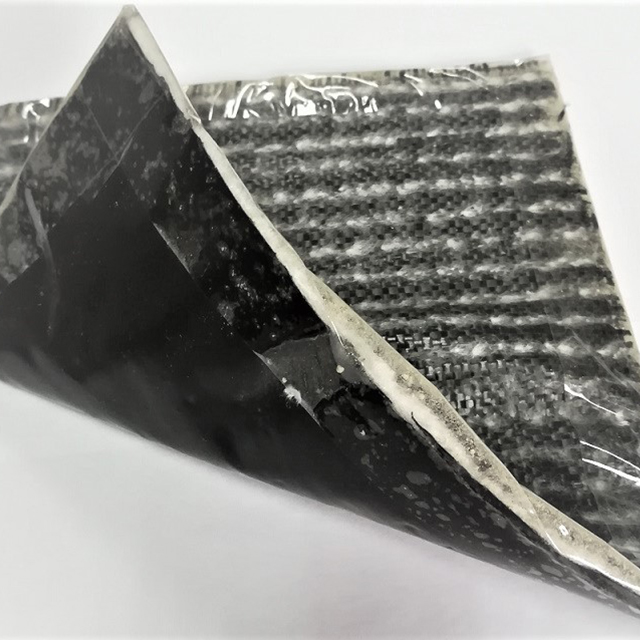

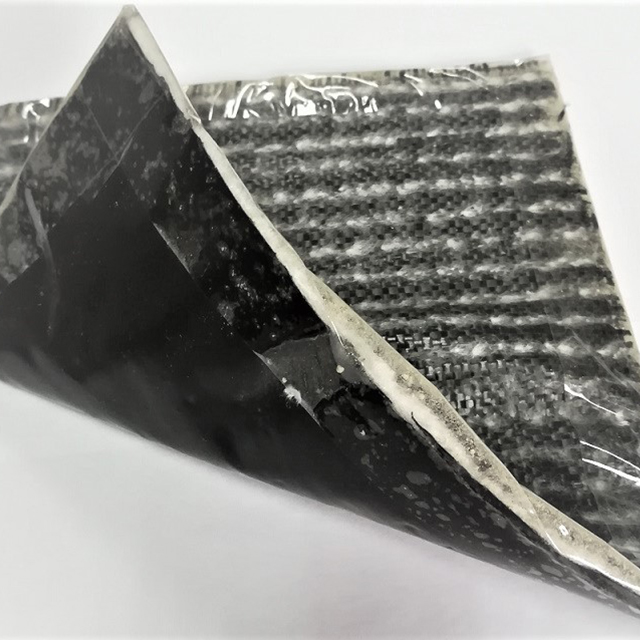

The 5kg Natural Sodium Bentonite Geosynthetic Clay Liner (GCL) is an innovative waterproof geosynthetic material designed by Yingfan, a trusted manufacturer with ISO9001/ISO14001/ISO45001 certification and over 17 years of industry experience. This high-performance liner is crafted by encapsulating natural sodium bentonite particles between two layers of durable geotextile using a special bonding process. Combining the advantages of geotextiles and bentonite, the GCL liner offers exceptional waterproof (seepage) performance, along with separation, reinforcement, protection, and filtration functions. Ideal for landfill projects, wastewater treatment facilities, and environmental engineering, this natural sodium bentonite geosynthetic clay liner provides a reliable, eco-friendly barrier that prevents contamination and ensures long-term structural integrity. Its easy installation and durable design make it a cost-effective choice for demanding waterproofing applications.

Specification | 5kg Model (4000-6000g/m²) |

Mass per Unit Area | 3000-6500 g/m² (5kg standard) |

Width | 3-6m (customizable) |

Base Material | Natural sodium bentonite + high-strength geotextile |

Key Feature | Excellent water swelling property and compactness |

Environmental Rating | Green and eco-friendly, non-toxic |

Application | Landfill waterproofing, seepage control |

Core Material: High-quality natural sodium bentonite, known for its superior water-swelling capacity (expands up to 15-20 times its original volume when in contact with water, forming an impermeable barrier).

Outer Layers: Two layers of durable geotextile, providing reinforcement, separation, and protection for the bentonite core.

Bonding Process: Specialized manufacturing technique that securely fixes bentonite particles between geotextile layers, preventing leakage and ensuring uniform distribution.

The natural geosynthetic clay liner leverages the water-swelling property of sodium bentonite to form a tight, impermeable seal, effectively preventing water seepage and contaminant leakage. It outperforms traditional waterproof materials in long-term durability and reliability.

Made from natural sodium bentonite and synthetic geotextile, the GCL liner is non-toxic, environmentally friendly, and compliant with global environmental standards. It does not release harmful substances, making it suitable for sensitive applications like landfills and wastewater treatment.

Beyond waterproofing, this liner offers separation, reinforcement, protection, and filtration functions. It strengthens the underlying soil structure, prevents soil erosion, and filters impurities, enhancing the overall stability of engineering projects.

The 5kg GCL liner features a lightweight design that simplifies transportation and installation. It requires minimal equipment and labor, reducing construction time and costs compared to traditional waterproofing methods (e.g., concrete liners). Its simple lap joint installation ensures quick and efficient deployment.

Serves as a primary waterproof barrier for municipal solid waste landfills, hazardous waste landfills, and sludge disposal sites, preventing leachate leakage into the soil and groundwater.

Wastewater treatment plants: Provides seepage control for lagoons, ponds, and storage tanks.

Mine tailings dams: Prevents heavy metal contamination by blocking seepage from tailings.

Artificial lakes and reservoirs: Ensures water retention and prevents soil seepage.

Road and railway construction: Waterproofs subgrades and prevents moisture damage to foundations.

Tunnel and basement waterproofing: Creates a reliable barrier against groundwater infiltration.

Embankment and slope protection: Prevents water seepage and soil erosion, enhancing slope stability.

Irrigation canals and ditches: Reduces water loss through seepage, improving irrigation efficiency.

Golf course ponds and landscape water features: Ensures water retention and maintains water quality.

Manufactured by an ISO9001/ISO14001/ISO45001-certified factory with strict quality control processes, ensuring consistent product performance.

Natural sodium bentonite meets international purity standards, guaranteeing optimal water-swelling and waterproofing capabilities.

The geotextile outer layers are tested for tensile strength, tear resistance, and durability, ensuring long-term reliability in harsh environments.

Complies with safety and environmental regulations, minimizing risks of contamination and structural failure.

Prepare the base surface: Ensure it is level, compacted, and free of sharp objects, rocks, or debris that could puncture the liner.

Unroll the 5kg GCL liner carefully, aligning it with the project's waterproofing area. Avoid dragging the liner to prevent damage.

Lap joints: Overlap adjacent liner edges by 15-20cm (or as per project specifications) to ensure a tight seal. Press the laps firmly to activate the bentonite's swelling property.

Secure the liner: Use anchor pins or weights to fix the liner in place, especially on slopes, to prevent displacement during backfilling.

Backfill: Cover the liner with a protective layer (e.g., soil, gravel) immediately after installation to avoid UV degradation and physical damage.

Inspect the liner regularly for punctures, tears, or displacement, especially after construction or extreme weather events.

Avoid exposing the liner to direct sunlight for extended periods before installation; store in a shaded, dry area.

Promptly repair any damage using compatible GCL patches or bentonite powder to maintain waterproof integrity.

Ensure proper drainage around the liner to prevent excessive water pressure buildup.

Unlike concrete or synthetic liners, our natural geosynthetic clay liner uses natural bentonite for waterproofing, offering superior eco-friendliness, self-healing properties (swells to seal small punctures), and easier installation.

Yes, it is specifically designed for landfill waterproofing, effectively preventing leachate leakage and protecting soil and groundwater quality.

Yes, we offer customization for mass per unit area (3000-6500g/m²) and width (3-6m) to meet specific project requirements.

We provide fast delivery times; contact our team for a detailed timeline based on your order quantity and location.

Elevate your waterproofing project with the 5kg Natural Sodium Bentonite Geosynthetic Clay Liner—a reliable, eco-friendly solution trusted by engineers worldwide. Send us an email today to inquire about pricing, request technical data sheets, or discuss customized specifications. Our expert team will respond within one business day to help you find the perfect waterproofing solution for your landfill, environmental, or civil engineering project. Choose Yingfan for quality, durability, and peace of mind—let’s build a more sustainable future together!

The 5kg Natural Sodium Bentonite Geosynthetic Clay Liner (GCL) is an innovative waterproof geosynthetic material designed by Yingfan, a trusted manufacturer with ISO9001/ISO14001/ISO45001 certification and over 17 years of industry experience. This high-performance liner is crafted by encapsulating natural sodium bentonite particles between two layers of durable geotextile using a special bonding process. Combining the advantages of geotextiles and bentonite, the GCL liner offers exceptional waterproof (seepage) performance, along with separation, reinforcement, protection, and filtration functions. Ideal for landfill projects, wastewater treatment facilities, and environmental engineering, this natural sodium bentonite geosynthetic clay liner provides a reliable, eco-friendly barrier that prevents contamination and ensures long-term structural integrity. Its easy installation and durable design make it a cost-effective choice for demanding waterproofing applications.

Specification | 5kg Model (4000-6000g/m²) |

Mass per Unit Area | 3000-6500 g/m² (5kg standard) |

Width | 3-6m (customizable) |

Base Material | Natural sodium bentonite + high-strength geotextile |

Key Feature | Excellent water swelling property and compactness |

Environmental Rating | Green and eco-friendly, non-toxic |

Application | Landfill waterproofing, seepage control |

Core Material: High-quality natural sodium bentonite, known for its superior water-swelling capacity (expands up to 15-20 times its original volume when in contact with water, forming an impermeable barrier).

Outer Layers: Two layers of durable geotextile, providing reinforcement, separation, and protection for the bentonite core.

Bonding Process: Specialized manufacturing technique that securely fixes bentonite particles between geotextile layers, preventing leakage and ensuring uniform distribution.

The natural geosynthetic clay liner leverages the water-swelling property of sodium bentonite to form a tight, impermeable seal, effectively preventing water seepage and contaminant leakage. It outperforms traditional waterproof materials in long-term durability and reliability.

Made from natural sodium bentonite and synthetic geotextile, the GCL liner is non-toxic, environmentally friendly, and compliant with global environmental standards. It does not release harmful substances, making it suitable for sensitive applications like landfills and wastewater treatment.

Beyond waterproofing, this liner offers separation, reinforcement, protection, and filtration functions. It strengthens the underlying soil structure, prevents soil erosion, and filters impurities, enhancing the overall stability of engineering projects.

The 5kg GCL liner features a lightweight design that simplifies transportation and installation. It requires minimal equipment and labor, reducing construction time and costs compared to traditional waterproofing methods (e.g., concrete liners). Its simple lap joint installation ensures quick and efficient deployment.

Serves as a primary waterproof barrier for municipal solid waste landfills, hazardous waste landfills, and sludge disposal sites, preventing leachate leakage into the soil and groundwater.

Wastewater treatment plants: Provides seepage control for lagoons, ponds, and storage tanks.

Mine tailings dams: Prevents heavy metal contamination by blocking seepage from tailings.

Artificial lakes and reservoirs: Ensures water retention and prevents soil seepage.

Road and railway construction: Waterproofs subgrades and prevents moisture damage to foundations.

Tunnel and basement waterproofing: Creates a reliable barrier against groundwater infiltration.

Embankment and slope protection: Prevents water seepage and soil erosion, enhancing slope stability.

Irrigation canals and ditches: Reduces water loss through seepage, improving irrigation efficiency.

Golf course ponds and landscape water features: Ensures water retention and maintains water quality.

Manufactured by an ISO9001/ISO14001/ISO45001-certified factory with strict quality control processes, ensuring consistent product performance.

Natural sodium bentonite meets international purity standards, guaranteeing optimal water-swelling and waterproofing capabilities.

The geotextile outer layers are tested for tensile strength, tear resistance, and durability, ensuring long-term reliability in harsh environments.

Complies with safety and environmental regulations, minimizing risks of contamination and structural failure.

Prepare the base surface: Ensure it is level, compacted, and free of sharp objects, rocks, or debris that could puncture the liner.

Unroll the 5kg GCL liner carefully, aligning it with the project's waterproofing area. Avoid dragging the liner to prevent damage.

Lap joints: Overlap adjacent liner edges by 15-20cm (or as per project specifications) to ensure a tight seal. Press the laps firmly to activate the bentonite's swelling property.

Secure the liner: Use anchor pins or weights to fix the liner in place, especially on slopes, to prevent displacement during backfilling.

Backfill: Cover the liner with a protective layer (e.g., soil, gravel) immediately after installation to avoid UV degradation and physical damage.

Inspect the liner regularly for punctures, tears, or displacement, especially after construction or extreme weather events.

Avoid exposing the liner to direct sunlight for extended periods before installation; store in a shaded, dry area.

Promptly repair any damage using compatible GCL patches or bentonite powder to maintain waterproof integrity.

Ensure proper drainage around the liner to prevent excessive water pressure buildup.

Unlike concrete or synthetic liners, our natural geosynthetic clay liner uses natural bentonite for waterproofing, offering superior eco-friendliness, self-healing properties (swells to seal small punctures), and easier installation.

Yes, it is specifically designed for landfill waterproofing, effectively preventing leachate leakage and protecting soil and groundwater quality.

Yes, we offer customization for mass per unit area (3000-6500g/m²) and width (3-6m) to meet specific project requirements.

We provide fast delivery times; contact our team for a detailed timeline based on your order quantity and location.

Elevate your waterproofing project with the 5kg Natural Sodium Bentonite Geosynthetic Clay Liner—a reliable, eco-friendly solution trusted by engineers worldwide. Send us an email today to inquire about pricing, request technical data sheets, or discuss customized specifications. Our expert team will respond within one business day to help you find the perfect waterproofing solution for your landfill, environmental, or civil engineering project. Choose Yingfan for quality, durability, and peace of mind—let’s build a more sustainable future together!