Views: 0 Author: Site Editor Publish Time: 2026-02-09 Origin: Site

Seepage can threaten landfills and mining sites.So, how does geosynthetic clay liner work?This article explains the geosynthetic clay liner working principle and GCL liner mechanism.You will learn how bentonite swelling creates a strong hydraulic barrier, with trusted solutions from Yingfan.

The first step in how does a geosynthetic clay liner prevent seepage is hydration. Inside the liner, there is a central layer of natural sodium bentonite. When water reaches this clay, it absorbs moisture fast. The bentonite then expands about 15 to 28 times its dry volume. This swelling is the key driver of the geosynthetic clay liner swelling and sealing process. Under soil cover, the clay cannot move freely. Instead, clay particles press together. They form a dense and uniform gel layer. This gel blocks pathways that liquids would use to escape. It is why GCL liners perform as strong hydraulic barriers in many containment systems.

Once bentonite swells, it creates a nearly impermeable seal. The clay gel fills internal voids and closes micro channels. This is the core of the geosynthetic clay liner hydraulic barrier function. Even though a liner is only 5 to 10 mm thick, it can provide the same hydraulic protection as several feet of compacted clay. This thin profile saves space in landfills and reservoirs. It also reduces excavation needs. Engineers value this performance because seepage control directly protects groundwater. It also reduces long term contamination risks. Many regulations demand this level of containment reliability.

Confinement is a critical part of the GCL liner mechanism. Bentonite swelling must happen under pressure from soil or structural weight. Without confinement, the clay could spread instead of sealing tightly. When confined, particles compress into a dense gel barrier. This is why cover soil placement is not optional. It ensures stable sealing and prevents erosion of the clay core. Proper confinement also supports long term durability during settlement or vibration. If confinement is weak, hydraulic performance may drop. So installation and design must always consider load conditions.

Tip: Always place cover soil quickly after installation to keep bentonite swelling controlled and effective.

One reason engineers trust GCLs is self healing. During installation, small debris may puncture the liner. In many materials, this would cause leaks. But a bentonite geosynthetic clay liner can self repair. When water enters the damaged zone, bentonite hydrates and migrates into the hole. It swells and seals the puncture automatically. This feature reduces the risk of seepage paths forming over time. It adds safety for landfill containment and mining projects. Self healing does not replace good construction. But it gives extra resilience in real field conditions.

Self healing also helps when nearby structures crack. Bentonite swelling can seal cracks in concrete up to about 2 mm wide. This makes GCL liners useful in underground garages and tunnel waterproofing. Settlement often creates small gaps. A liner that can adapt provides stronger protection. The swelling clay maintains contact with surfaces and prevents water migration. This ability supports long term performance in infrastructure projects. It also reduces maintenance needs compared to rigid clay barriers.

Self healing has limits. Large tears or major displacement cannot always be sealed. If confinement is missing, bentonite may erode instead of forming a barrier. Chemical exposure can also affect swelling behavior in some cases. This is why quality control remains essential. Overlaps, seam treatments, and subgrade preparation must still be done correctly. Engineers should view self healing as an added safety layer. It improves reliability but does not remove installation responsibility. Proper design reduces the chance of severe liner damage.

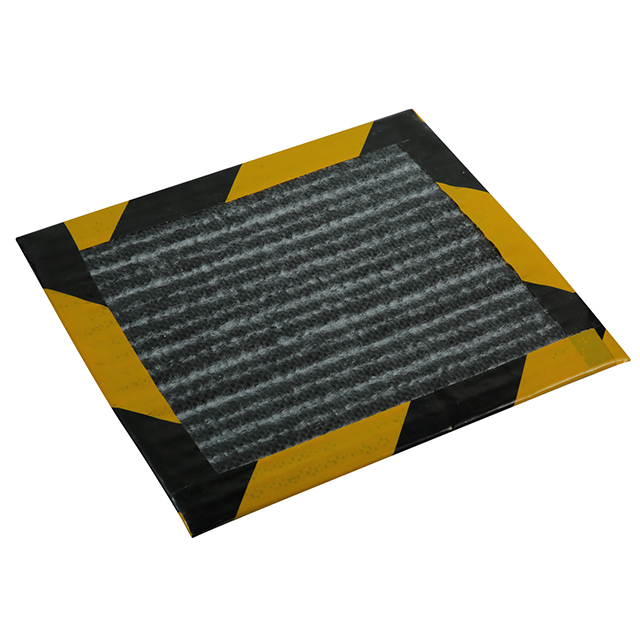

Most GCL liners use a geotextile encased structure. Bentonite is sandwiched between woven and non woven fabrics. These fabrics protect the clay and provide strength. Needle punching or stitching bonds the layers together. This mechanical bond gives high internal shear resistance. It allows liners to be used on steep slopes. The geotextiles also prevent bentonite migration. They keep the clay evenly distributed during swelling. This structural design is essential for stable sealing performance. Many engineered GCL liner products, including those from Yingfan, highlight this three-layer needle-punched structure for long-term containment reliability.

Main Component | Function in the Working Mechanism | Benefit |

Bentonite core | Swells and forms gel barrier | Low permeability sealing |

Geotextile layers | Reinforce and protect clay | Durability and stability |

Needle punching | Locks layers together | Higher shear strength |

Some projects require extra protection. In these cases, bentonite is bonded directly to a geomembrane such as HDPE. This creates a dual barrier system. The geomembrane provides polymer impermeability. The bentonite provides self sealing and healing. Together, they improve containment in harsh environments. Dual systems are common in hazardous waste sites. They also help where gas control is needed. This design expands the range of geosynthetic clay liner applications.

Needle punching is one of the most important reinforcement methods. Fibers are punched through the clay core. This locks fabrics together and improves shear strength. High shear resistance matters on slopes and embankments. It reduces liner sliding risk during settlement. Needle punched liners also handle installation stresses better. They remain stable even under heavy cover loads. This makes them suitable for large landfill caps and mining tailings dams. Structural bonding supports long term containment safety.

A major question is how does GCL liner work compared to compacted clay. The main difference is thickness. A single GCL, only a few millimeters thick, can match several feet of compacted clay. This equivalency reduces soil import needs. It also increases usable containment volume. Thin liners are easier to handle and deploy. They also provide consistent factory controlled performance. For many engineers, this is a key reason to specify GCLs.

Feature | GCL Liner | Compacted Clay Liner |

Thickness | Few millimeters | Hundreds of millimeters |

Installation speed | Fast, roll-based | Slow, labor intensive |

Sealing mechanism | Bentonite swelling | Soil compaction |

Cracking risk | Low, flexible | Higher in freeze-thaw |

Compacted clay liners require heavy equipment and strict moisture control. Construction takes time and skilled labor. GCL liners come in wide rolls. They can be installed quickly using standard equipment. This reduces project schedules and labor costs. Factory manufacturing ensures consistent bentonite mass and bonding quality. Field variability is lower than compacted soil barriers. This makes GCL liners attractive for large scale projects. Fast installation also reduces exposure to weather delays.

Compacted clay can crack during freeze thaw cycles. It may also crack during settlement. GCL liners remain flexible. They adapt to minor ground movement without losing sealing ability. Bentonite swelling can reseal small gaps. This makes them more robust in cold climates and dynamic sites. Reduced cracking lowers long term maintenance needs. It also improves reliability in infrastructure waterproofing projects. Flexibility is one reason GCL use continues to grow.

Landfills generate leachate that must not escape. GCL liners are widely used as landfill base liners and caps. Their bentonite swelling forms a strong barrier against leachate migration. This supports groundwater protection and regulatory compliance. Self healing adds extra safety against minor punctures. Landfill containment remains the largest global application for GCLs. Engineers often combine them with geomembranes for added protection. The working principle directly supports long term waste isolation.

Mining sites often contain toxic chemicals. Tailings dams and heap leach pads need reliable seepage control. Geosynthetic clay liner for mining projects provides strong containment. The liner blocks migration of contaminated fluids. Reinforced designs handle heavy loads and slope stresses. Self sealing reduces risk from small installation damage. Mining containment is one of the most demanding uses. GCL performance under harsh conditions makes it a preferred solution.

Water loss through seepage can waste resources. GCL liners help line reservoirs, canals, and ponds. They prevent seepage and protect surrounding soils. Their thin profile reduces excavation compared to thick clay layers. Installation in wide rolls speeds construction. Water containment projects benefit from long term durability. Bentonite is a natural inorganic material. It resists aging and corrosion. This supports permanent waterproof performance in water infrastructure.

Underground structures often face groundwater pressure. Basements, tunnels, and garages need waterproof barriers. GCL liners provide a flexible containment layer. They can seal cracks and adapt to settlement. This reduces infiltration risks. Infrastructure waterproofing is growing as cities expand. GCL liners also support road and railway subgrade stabilization. Their working principle makes them versatile beyond waste containment.

Application Area | Main Containment Goal | Why GCL Works Well |

Landfills | Stop leachate migration | Swelling bentonite seal |

Mining tailings | Contain toxic fluids | Strong hydraulic barrier |

Reservoirs and ponds | Prevent water loss | Thin waterproof liner |

Underground structures | Block groundwater infiltration | Flexible self-healing layer |

Subgrade preparation is the first defense against liner damage. Sharp stones and debris can puncture the liner. The base must be smooth and compacted. Wrinkles must be avoided. Proper preparation ensures uniform contact between liner and soil. It reduces stress points that may cause tears. Engineers should inspect surfaces before placement. Good preparation improves long term hydraulic performance. Poor preparation increases risk of leakage paths. Installation quality directly affects containment success.

Panel overlaps ensure continuous sealing. If overlaps are too small, seepage paths can form. Proper lap joint design keeps bentonite continuity across seams. Some projects add bentonite powder or paste at overlaps. This improves sealing. Seam quality control is essential in landfills and reservoirs. Poor seam execution can compromise the entire barrier system. Engineers must follow installation guides carefully. Overlaps are simple but critical details.

Cover soil protects the liner from weather and damage. It also provides confinement for swelling. Without cover, bentonite may hydrate too early. Wind and rain can erode exposed edges. Immediate cover placement prevents these risks. Hydration should occur under controlled confinement. This ensures gel formation and low permeability. Proper cover thickness also prevents mechanical damage. Installation timing is a key success factor.

Note: Exposed GCL panels should be weighted quickly to prevent wind uplift before cover placement.

Geosynthetic clay liner price depends on bentonite mass and specifications. A common example is around US$1 per square meter for standard 4800g products, but costs vary by market and design needs. Price also depends on bonding method and reinforcement. Engineers should compare installed cost, not only material cost. Faster installation often reduces labor expense. Project scale also influences procurement pricing. Cost must be evaluated alongside risk reduction benefits.

Bentonite is a natural inorganic material. It does not age or corrode easily. This gives long term waterproof performance. GCL liners remain flexible and resist cracking. They also self heal minor punctures. These factors reduce maintenance needs. Long service life improves lifecycle value. For regulated projects, durability supports compliance over decades. Engineers often choose GCLs for permanent containment systems. Reliability is a key driver of adoption.

Environmental protection requires strong containment. Seepage can cause groundwater contamination and costly remediation. GCL liners reduce these risks. They provide robust hydraulic barriers in waste, mining, and water projects. Their thin design saves space and cost. Self sealing adds resilience. These benefits support high value in critical infrastructure. Many agencies now specify GCLs as standard containment solutions. They help protect communities and ecosystems.

Geomembranes are polymer sheets, often PE based. They provide impermeability through synthetic material. GCLs provide impermeability through bentonite swelling and gel sealing. The working mechanisms differ. Geomembranes rely on perfect sheet integrity. GCLs rely on swelling and self healing. Both can be effective. Selection depends on site conditions and chemical exposure. Understanding these differences supports better design decisions.

A key advantage of GCL liners is self healing. Minor punctures can seal automatically. Geomembranes usually require manual repairs. This makes GCLs more forgiving during installation. Self healing reduces risk of small defects causing leaks. It improves reliability in rough subgrades. Engineers often value this feature in landfill and mining containment. It adds a safety margin in real world construction.

Many high risk projects use composite systems. They combine geomembranes with GCL liners. The geomembrane provides a strong synthetic barrier. The GCL provides self sealing and backup protection. Composite liners are common in hazardous waste containment. They improve redundancy and long term performance. This approach reduces environmental risk. It also meets strict regulatory requirements. Composite design reflects best practice in containment engineering.

Geosynthetic clay liners work through bentonite hydration and swelling under confinement.This creates a dense gel barrier that blocks seepage and protects groundwater.Self-healing seals small punctures, while geotextiles add strength and stability.Used in landfills, mining, and reservoirs, Yingfan GCL solutions provide durable containment value.

A: It works through bentonite swelling, forming a dense hydraulic barrier that blocks seepage.

A: The geosynthetic clay liner working principle relies on hydration and sealing under confinement.

A: Swelling bentonite can seal small punctures, improving containment reliability in landfills.

A: A GCL liner offers similar protection in a thinner profile, with faster installation and less cracking.